Description

The Six Sigma Yellow Belt certification was developed to encourage the candidates to be responsible for the development of Lean Six Sigma Implementation throughout their organizations. This course is designed for Supervisors and Executives who are responsible for designing and implementing corporate wide improvement and cost optimization initiatives. Yellow belts can be entry level employees who seek to improve their world or executive champions who require an overview of Six Sigma and define, measure, analyze, improve and control model (DMAIC).

- Manager

- Executive Officers

- Supervisor

- Executives & Others

- Business Process Improvement

- Change Management

- Transformation Department

- Continuous Improvement

- Project Management

- Production Management

- Contract Department

- Innovation Department

- Commercial Department

- Business Development

- Strategic Planning

- Human Resource

- Finance & Others.

- During the training, the project will emphasize on the workshops that entails the project outputs that are required.

- The Yellow Belt participants will have more in-depth knowledge of Lean and Six Sigma, and each of the five phases that are to be applied in practical terms.

- This course is designed to provide a broad understanding of the Lean and Six Sigma improvement methodology, concepts, and language, along with a complete toolbox of basic process improvement methods.

- The Six Sigma Yellow Belt course is designed to enhance technical problem solving skills. Instruction is application focused, therefore requiring all participants to successfully support existing or new Lean and Six Sigma projects.

- The Yellow Belt upon completion of this training will participate as a core team member or subject matter expert on a project or projects together with the supervisors/managers.

- The tools and deliverable of the Six Sigma Yellow Belt Program modules / topics are as below.

- Simulation Activities

- Own Software

- Own Books

- Q & A

- Group Discussions

- Case Study

- Talk over Tea

- Networking

We will administer an examination for the participants upon completion of their training. The examination consists of the following (on last day of training):

Lean Six Sigma Yellow Belt Level (Internal – SSC Certified)

Exam Type : Multiple Choice Questions

No. of Questions : 30 Questions

Examination : Open Book Examination

Passing Rate : 70% and above

Duration of Exam : 1 Hour

Location of Exam : At training location

Cost : Inclusive of training

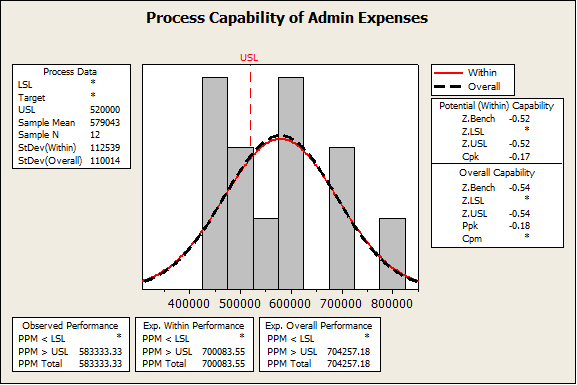

Where applicable, during the training course, our consultants will provide the participants with training on how to analyse Quality data using the Minitab software which is widely used by Lean Six Sigma practitioners.

Example of Minitab Software:

OUR CONSULTANTS WILL ALSO PROVIDE CANDIDATES WITH USEFUL EXCEL QUALITY TEMPLATES AND TOOLS

Lean Six Sigma Yellow Belt: Curriculum

- Overview of Six Sigma – DMAIC & DMADV

- DMAIC vs. Other Approaches

- Cost of Poor Quality (COPQ)

- Understanding Project Charters and Prioritisation Tools

- Root Cause Analysis (RCA) Tools

- Data Collection Technique

- Basic Lean Enterprise

- Workshop Sessions

- Basic Statistics and Graphical Analysis

- Creating Fishbone Diagrams

- Understanding Value Added (VA) and Non-Value Added Activities (NVA)

- Types of Statistical Analysis (Quantitative & Qualitative)

- Workshop Sessions

- Generating Improvement Ideas

- Poke – Yoke (Mistake Proofing)

- Running Pilot Six Sigma Programmes

- Solutions Implementation Plan

- Understanding Statistical Process Control

- Establishing Control Plans

- SOP & Documentation

- Workshop & IASSC Examination Sessions

Reviews

There are no reviews yet.