Lean Six Sigma methodology & Industry 4.0

Industry 4.0 stands for the fourth industrial revolution which is defined as a new revolution in the aspect of organizational practices that are geared towards increasing customers’ satisfaction and fulfilling their requirements through the use of data and cyber-physical system

The Transition from Industry 3.0 to Industry 4.0

Industry 3.0 centres on the introduction of automated systems into the assembly of performing human tasks. The third industrial revolution has implemented the use of computers, machinery and automation from which the fourth industrial revolution has evolved into. Manufacturing and automation became advanced with the help of Internet, connectivity and renewable energy. The growth in automation production has also redefined communication proceses due to the presence of digital and exponential nature. Even though Information Technology is widely implemented, it still relied on human input and intervention.

The highlight of the transition between Industry 3.0 to Industry 4.0 is the intervention of human. The improvement in the fourth industrial revolution is the enhancement of automation with the aid of connectivity. It allows people to experience “smart” industry that undergoes transformation and development in multiple sectors.

What are the key elements of Industry 4.0?

Two of the main drivers of Industry 4.0 are Big Data and Internet of Things

Big Data

Gartner (2013) defines Big Data as high volume, velocity and variety of information assets where cost effective, innovative forms of information processing for improved insight, decision making and process automation are demanded. Features of big data are digitally generated, passively produced and automatically collected.

Data analytics can help to identify problems that occur in a process and forecast issues that may arise in the future. The data can be extracted from various sources; transaction systems, customer databases, medical records, social networks and more.

Internet of Things (IoT)

The advancement of technology enabled people to be connected to one of the biggest and transformative innovations in the world, the Internet. The Internet of Things (IoT) allows the mechanical and digital machines along with appliances to connect, interact and exchange data. “It’s about networks, it’s about devices, and it’s about data,” explained Caroline Gorski, the head of IoT at Digital Catapult. The connectivity is not limited to standard devices such as laptops, smartphones and computers but also cars, kitchen, and personal devices as well. The application of IoT devices is usually categorized into consumer, commercial, industrial, infrastructure and spaces.

Smart Home is an example of the application of IoT where it is equipped with the technology that enables the house devices such as smart thermostat, lighting, heater, security cameras and other devices to interact with one another to perform tasks. These devices work by communicating with each other or sharing the data to the cloud to be analysed. Human’s intervention is not much needed, unless when it is needed for commandment.

Lean Six Sigma

Lean Six Sigma focuses on business improvements by adopting and combining the key features of Lean and Six Sigma into a single approach towards business performance enhancement (Hill, Thomas, Mason-Jones & El-Kateb, 2017). Lean focuses on eliminating waste that can be categorized into three types which are “Muda”, “Muri” and “Mura”. “Muda” is the non-value added activities where processes or activities are required to be distinguished as value adding, value enabling and non-value adding. On the other hand, “Muri” is the unreasonable work that is inflicted on workers due to poor organization while “Mura” is known as a variation that exists with the increase in demand, where it requires extra productivity from the organization which eventually leads to “Muri” and “Muda”.

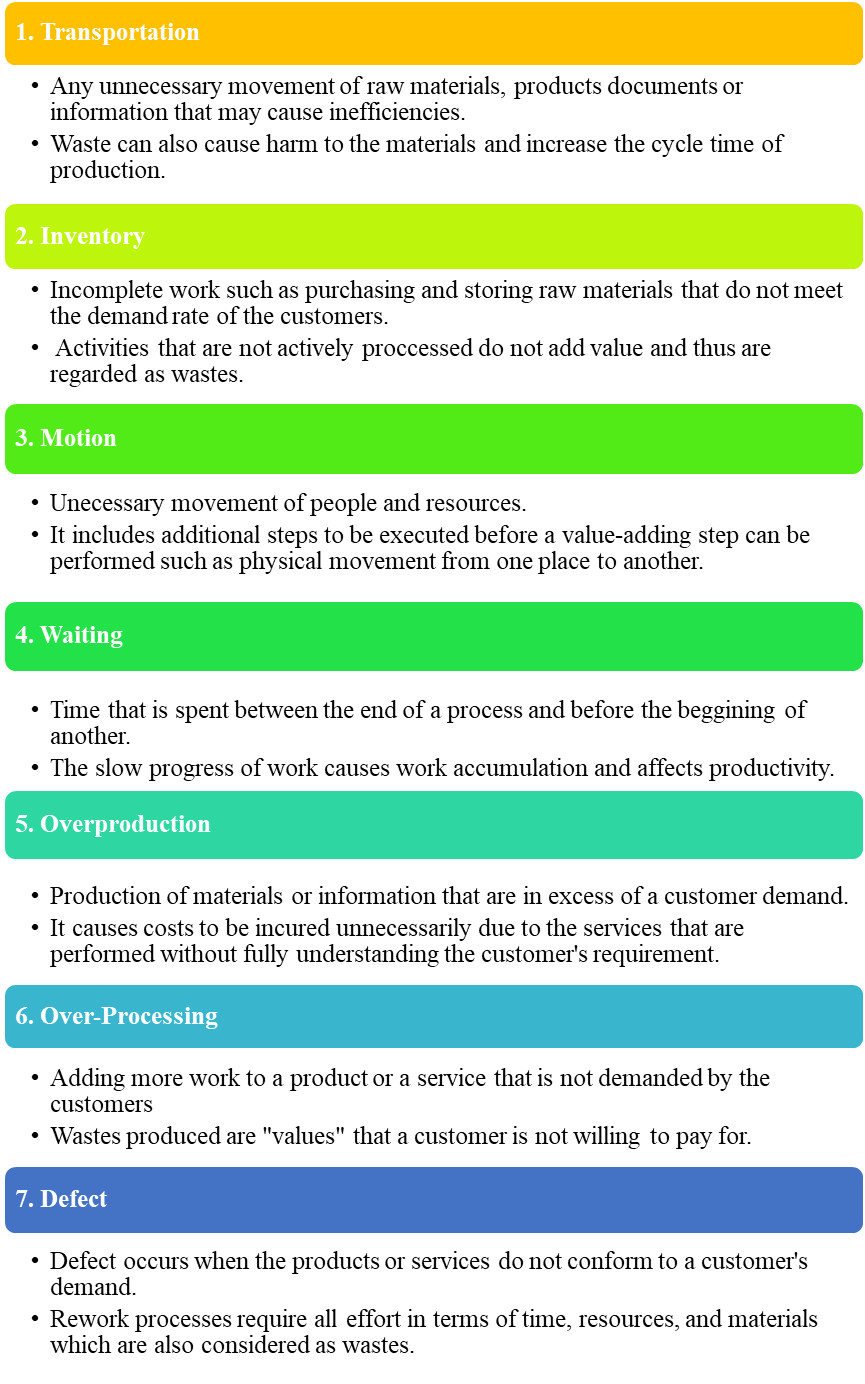

Taiichi Ohno, the Toyota’s Chief Engineer developed ‘The Seven Wastes’ as the core of Toyota’s Production System which is also known as Lean Manufacturing. The Seven Wastes can be labelled as transport, inventory, motion, waiting, overproduction, over-processing and defects.

Seven Wastes of Lean

Six Sigma reduces the amount of variation in processes and centres on quality improvement. Variation is unwanted as it creates uncertainty that affects productivity. The combination accelerates quality improvement and minimizes waste that can improve an organization’s operational cost and capital.

How Does Internet of Things (IoT) and Big Data Work?

The huge number of devices connected to IoT contributes to the increase of data consumption. Ahmed et al (2017) explained that sensors that are embedded in devices are applied in nearly all industries and thus, encouraging IoT to produce enormous amount of data. The data will then be used to find potential research trends which can be used to analyze the influence of events or decisions. IoT and Big Data overlap with each other. Technology that is introduced by the fourth industrial revolution allows the application of data mining techniques which are Big Data Analytics and Data Mining.

Data Analytics

Data analytics can be defined as the process of organizing raw and large data received by sources such as smart devices to uncover useful information that may help in decision making process. Dogan and Durcan (2018) in their research clarified that various Big Data techniques including machine learning, text mining and video mining can be used in Lean Six Sigma cycle to gain deeper insight into processes.

Data Mining

Nadkarni (2016) defined Data Mining as a process of identifying pattern and information from a large set of data. Lean Six Sigma methodology benefits from data mining techniques by using the data to make decisions for quality improvement and address quality issues. In order to gain insights from Big Data, data mining techniques that are used are association rule learning, classification analysis, clustering analysis, anomaly or outlier detection and regression analysis.

How does Big Data and Internet of Things (IoT) Assist in the Application of Lean Six Sigma methodology?

Big Data and IoT offer extensive set of data that can be extracted in order for the quality improvement process to take place. The application of Lean Six Sigma methodology requires a sufficient amount of data to improve operational efficiency. The objectives of Six Sigma and Big Data are similar which are to enable them to cooperate in order to achieve efficiency in an organization. Six Sigma eliminates defects and improves processes while Big Data helps to gain deeper insights into processes (Goswami, 2014).

DiLeo (2017) explained that the methodologies of Six Sigma are built on data and data delivers the visibility to the IoT work environment. He also added that IoT- driven data is crucial in order to define a problem. The basis of Lean Six Sigma methodology is identifying the root of the problem. The information gathered from Big Data and IoT can be capitalized in Lean Six Sigma methodology to convert data into actionable business intelligence.

Industry 4.0 provides an enormous amount of data in which they can be collected and analysed for corrective measures to be taken. Through the information from the extracted data, non-value added activities can be pinpointed more accurately and thus, it encourages a production system that focuses on quality. The compilation of data is used to investigate and predict areas that require adjustments.

Big Data involves advanced analytical practice and it can be incorporated in Lean Six Sigma projects due to the statistical techniques that are taught in the training programs. Linking Lean Six Sigma with Big Data allows the practitioners to use the accumulated data to search for insights that can aid process improvement. A research is conducted on the use of Lean Six Sigma as the quality improvement method.

According to Fogarty (2015), Six Sigma may benefit from using Big Data where the implementation of Big Data analytics has proven to be successful by companies such as Intel and GE Aviation. Intel managed to save $3M by using Big Data for preventive analysis and estimated a saving of over $30 million for the next few years. GE Aviation also estimated an increase in production speed by 25% with the implementation of Big Data analytics in the process inspection.

Lopresti (2017) discussed how predictive analytics and Lean Six Sigma were used in healthcare setting. The Winship Cancer Institute of Emory University in Georgia used predictive analysis on the volume of patients and the mix of treatments they asked for from the institute and based on the information, they took the Lean approach and managed to staff the needed number of nurses and phlebotomists at the right time. The institute was able to cut its waiting time from about one hour to less than fifteen minutes.

Moreover, organizations which offer business models that revolve around data are a step ahead than other competitors. Motorola and IBM implemented Six Sigma methodology where the process, organization structures and metrics were designed to achieve Six Sigma’s “zero defect” philosophy (Goswami, 2014).

In manufacturing, SupplyChainBrain (2018) elaborated on IoT which allows companies to collect common manufacturing metrics (cycle time, changeovers, utilization) as well as contextual data (ambient temperature, position, operator). This collection of data can be implemented in a process improvement method such as Six Sigma which affects the manufacturing performance positively.

Although that technology in today’s world provides a huge opportunity for improvements in many sectors, choosing the best way to put it into use is significant as well. Aligning Industry 4.0 with Lean Six Sigma methodology helps to utilize the vast amount of data acquired in order to improve the overall operation efficiency and provide better products and services to customers.

References

Ahmed, E., Yaqoob, I., Hashem, I. A. T., Khan, I., Ahmed, A. I. A., Imran, M., & Vasilakos,

- (2017). The role of big data analytics in Internet of Things. Computer Networks, 129, 459-471.

Brain, S. C. (2018, February 9). How Big Data is Revolutionizing Six Sigma Application in

Manufacturing. Retrieved from https://www.supplychainbrain.com/articles/27588-how-big-data-is-revolutionizing-six-sigma-application-in-manufacturing

Burgess, M. (2018, February 16). What is the Internet of Things? WIRED explains. Retrieved

from https://www.wired.co.uk/article/internet-of-things-what-is-explained-iot

Dileo, M. (2017, February 22). Six Sigma and the IoT Workplace: Internet of Things Brings a

New World of Opportunity. Retrieved February 15, 2019, from https://www.business.com/articles/six-sigma-and-the-iot-workplace-internet-of-things-brings-a-new-world-of-opportunity/

Dogan, O., & Gurcan, O. F. (2018). Data Perspective of Lean Six Sigma in Industry 4.0 Era:

A Guide to Improve Quality. Proceedings of the International Conference on Industrial Engineering and Operations Management Paris, France, July 26-27, 2018. Retrieved from http://www.ieomsociety.org/paris2018/papers/170.pdf.

Fogarty, D. (2015). Lean Six Sigma and big data: Continuing to innovate and optimize business

processes. Journal of Management and Innovation, 1(2), 2-20.

Goswami, B. (2016, November 29). Why Six Sigma Learnings are relevant for Big Data?

Retrieved from https://www.ibm.com/blogs/insights-on-business/electronics/why-six- sigma-learnings-are-relevant-for-big-data/

Hill, J., Thomas, A. J., Mason-Jones, R. K., & El-Kateb, S. (2018). The implementation of a

Lean Six Sigma framework to enhance operational performance in an MRO facility. Production & Manufacturing Research, 6(1), 26-48.

Laux, C., Li, N., Seliger, C., & Springer, J. (2017). Impacting big data analytics in higher

education through six sigma techniques. International Journal of Productivity and Performance Management, 66(5), 662-679.

Lopresti, J. (2016, October 26). Combining Lean Six Sigma with Big Data in Healthcare.

Retrieved from https://www.sixsigmadaily.com/combining-lean-six-sigma-big-data-healthcare/