Description

Lean Six Sigma is a proven systematic approach to improve measurable results for any organization. The Lean Six Sigma Black Belt training takes organizations to the next level by uniting product and process excellence with goals such as improving customer service and/or enhancing shareholder value creation. Leaders in today’s organizations are turning to the Lean Six Sigma Black Belt training to ensure their competitive edge, improve service and build the skill base needed to sustain performance improvement.

- Chief Executive Officers

- Managing Directors

- Executive Officers

- General Managers

- Managers

- Executives & Others

- Business Process Improvement

- Change Management

- Transformation Department

- Continuous Improvement

- Project Management

- Production Management

- Contract Department

- Innovation Department

- Commercial Department

- Business Development

- Strategic Planning

- Human Resource

- Finance & Others

- The Black Belt Course is designed to improve process performance, deliver high-impact projects and achieve significant cost savings.

- The Certified Lean Six Sigma Black Belt is a professional who can explain Lean Six Sigma philosophies and principles, including supporting systems and tools.

- Black Belts will demonstrate team leadership, understand team dynamics and assign team member roles and responsibilities.

- Black Belts will gain thorough understanding of all aspects of the DMAIC model in accordance with Six Sigma principles.

- Black Belts will gain knowledge of Lean enterprise concepts, are able to identify non-value-added elements and activities.

- Simulation Activities

- Own Software

- Own Books

- Q & A

- Group Discussions

- Case Study

- Talk over Tea

- Networking

We will administer an examination for the participants upon completion of their training. The examination consists of the following (on last day of training):

LSS BLACK Belt Level (Internal – SSC Certified)

Exam Type : Multiple Choice Questions

No. of Questions : 50 Questions

Examination : Open Book Examination

Passing Rate : 70% and above

Duration of Exam : 2 Hours

Location of Exam : At training location

Cost : Inclusive of training

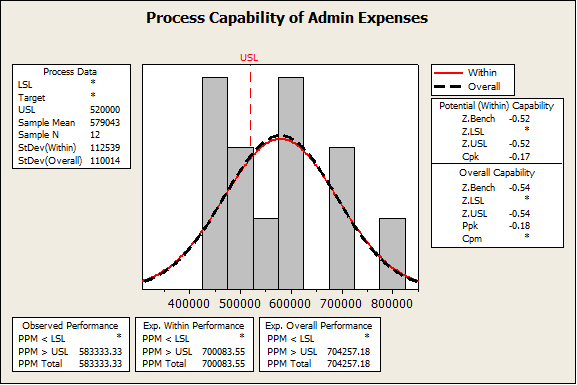

Where applicable, during the training course, our consultants will provide the participants with training on how to analyse Quality data using the Minitab software which is widely used by Lean Six Sigma practitioners.

Example of Minitab Software:

OUR CONSULTANTS WILL ALSO PROVIDE CANDIDATES WITH USEFUL EXCEL QUALITY TEMPLATES AND TOOLS

Lean Six Sigma Black Belt Accelerated: Curriculum

Define & Measure Phase

- Introduction & Overview of Six Sigma

- Cost of Poor Quality (COPQ)

- Drill Down Tree & Pareto Chart

- Project Charter Development

- Teams & Stakeholder Analysis

- Voice of Customers (VOC) & Kano Model

- SIPOC & Basic Process Mapping

- Quality Functional Deployment (QFD)

- Financial Analysis and Cost Savings

- Root Cause Analysis (RCA) Tools

- Cause & Effect Matrix

- Operational Definition

- Data Collection Plan

- Basic Statistics and Sampling Techniques

- Regression Analysis

- Value Stream Mapping (VSM)

- Summarizing Potential Factors and Potential Solutions

- Correlation Analysis

- Multiple Regression

- Simple Linear Regression

- Best Subset Regression

Analyze Phase

- Hypothesis Testing

- Measurement System Analysis (MSA)

- Capability Analysis and Sigma Value

- Graphical & Value Analysis

- Detailed Process Mapping

- Fishbone Diagram

- Failure Modes and Effects Analysis (FMEA)

- Advanced Statistical Root Cause Analysis tools:

- Type 1 & Type 2 error

- Degree of Freedom

- Power and Sample Size

- 1 Sample t-Test

- 2 Sample t-Test

- One way ANOVA

- Test of Equal Variance (TOEV)

- 1 Proportion Test

- 2 Proportion Test

- Chi-Square Test

- Non-Parametrics Analysis and Two Way ANOVA

- Advanced Graphical Analysis

- Sigma Value / Z-Bench

- Graphical Tools for Statistics

- Pareto Charts

- Box Plots

- Run Charts

- Dot Plots

- Scatter Plots

- Matrix Plots

- Histograms

- Time Series Plots

Improve & Control / 3 Days

- Generating Improvement Ideas

- Design of Experiment (DOE)

- Evaluating & Selecting Best Solutions

- Solution & Training Implementation Plan

- Develop & Execute Pilot Plan

- Lean Enterprise

- Cost & Benefit Analysis (ROI)

- Process Control Plan

- Standard Operating Procedures (SOP)

- Statistical Process Control (SPC)

- Best Practice and Replication Opportunities

- Process Ownership and Dashboards

Reviews

There are no reviews yet.